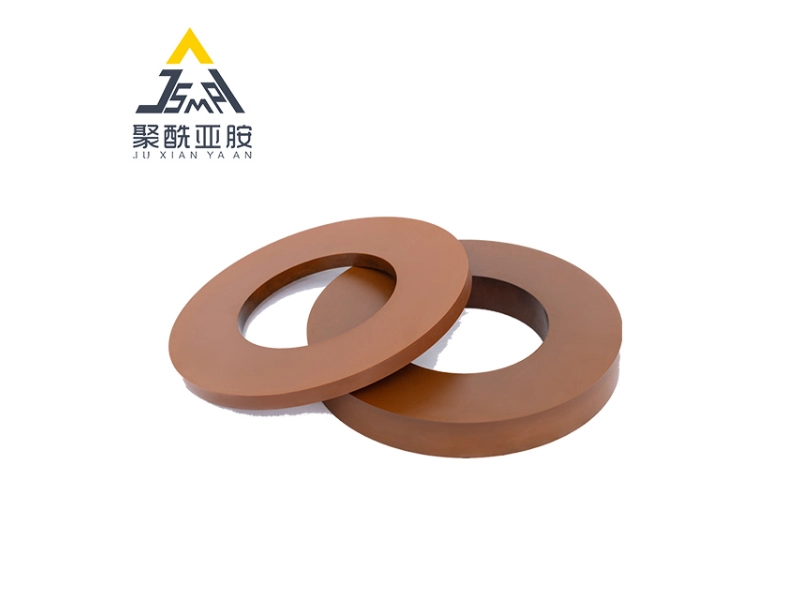

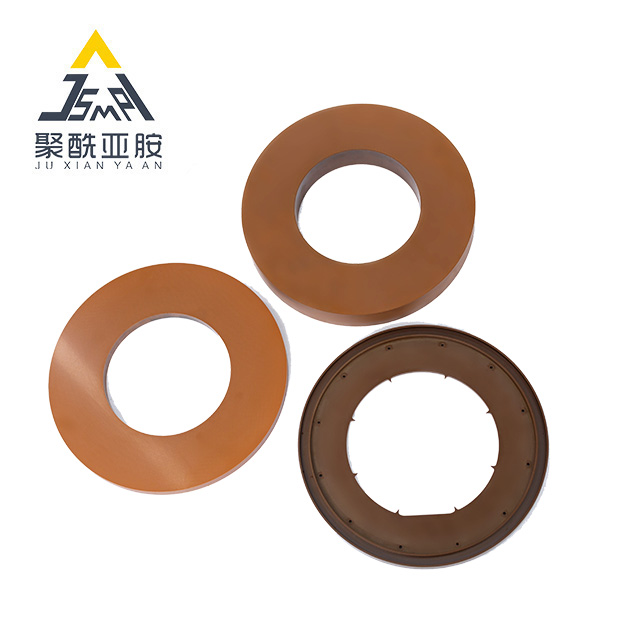

The heat-insulating cap (color-changing sleeve) is a workpiece between the nozzle tip and the mold gate (without plastic coating) instead of the heat-insulating plastic layer. It reduces the yellowing/discoloration of plastic in the dead corner due to long-term high temperature. It is also suitable for producing white plastic products with good aesthetic effects. When injecting color-changing plastic products, it can shorten the color-changing time and improve the efficiency of the hot runner system.